Overview

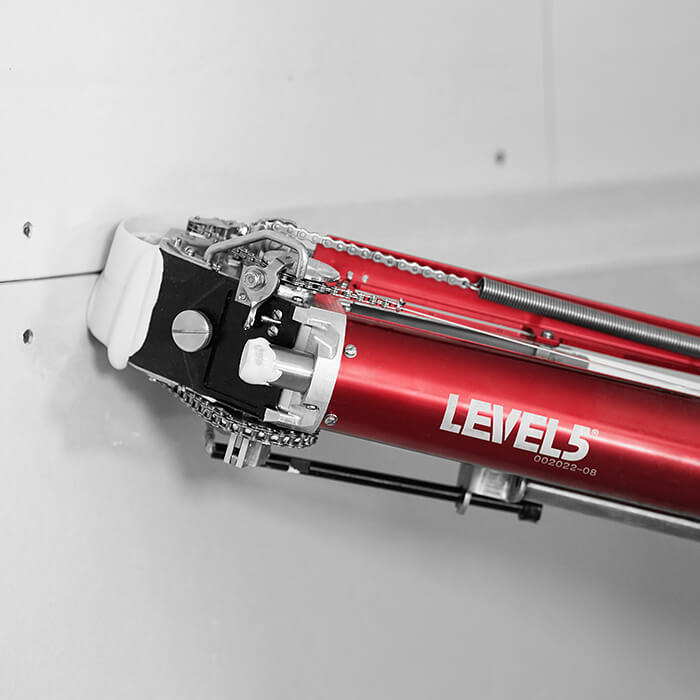

The LEVEL5 Automatic Drywall Taper is used to simultaneously apply the optimal amount of joint compound and tape to wall and ceiling joints. This automatic taper is a true workhorse in the industry.

Every component has been carefully designed to ensure the auto taper is lightweight while providing the highest durability, reliability, and corrosion resistance. The fit, finish and ultra-smooth operation of the LEVEL5 Automatic Taper are unparalleled at this value point.

Every LEVEL5 Automatic Taper [2nd Gen] also includes:

- (2) additional cutting blades

- (3) additional tape advancing needles

- (1) replacement creaser wheel spring

- (1) tape jam tool

- (2) garden hose nozzle adapters (for easy cleanup)

- (1) gooseneck cleaning brush

2ND GENERATION ENHANCEMENTS

- A new hollow drive wheel reduces weight and operates with less compound accumulation.

- All hardware mounting bands upgraded to stainless steel for a tighter grip and increased durability.

- New robotically-welded, one-piece stainless steel push rod assembly and precision machined one-piece stainless steel drive sprocket provide greater strength and long-term durability.

- A lighter-weight cutter spring provides easier tape cutting.

- Cutter rod guide is now precision machined and hard-coat anodized for smoother operation.

- Cutter change rod now hard-coat anodized for smoother operation.

- Cutter change rod also features a new design for easy removal.

- A new proprietary urethane rubber internal plunger cup provides smoother operation, 100% seal and long wear life.

- The tape roll assembly has been upgraded to machined billet aluminum with hard-coat anodizing and the design has been updated for easier tape roll loading.

- An adjustable tensioner on tape spool ensures the tape roll can’t free wheel when its not under load.

- A heavier gauge tape roll keeper rod doesn’t bend under the weight of the tape roll.

- The creaser trigger and its mounting base have been upgraded to precision- machined billet aluminum with hard-coat anodizing.

TIPS & TRICKS

- We recommend you use general purpose finishing compound or general purpose “lightweight” finishing compound. You can also use “machine mud” which is designed specifically for automatic finishing tools, but it can be more expensive and harder to source. DO NOT use any type of durabond or “hot muds”, as these fast setting compounds could harden inside your automatic taper - requiring you to break your taper down and manually clean every component.

- When you first start using the automatic taper, it is suggested you practice using it on scrap drywall or a practice board, so you can get a feel for:

- Getting the correct mud consistency. It should be thin enough so that the taper runs smoothly along the seam, but thick enough that the tape remains in place on the wall

- Setting the drive wheel brake. The drive wheel brake ensures the drive wheel doesn’t spin backwards when you pull the taper off the wall due to pressure from the cable - as this will create gaps in the mud that is applied behind the tape. You want the brake to be set just enough so that there is not any noticeable resistance and the taper moves smoothly along the seams.

- Setting the tape advancing (“gooser”) needle. The automatic taper is set up from the LEVEL5 factory to be used with paper tape. If you are using Fibafuse mesh tape, which is slightly thicker, you will need to back off the advancing needle so that the tape advances correctly when you activate the cutting mechanism.

- PRO TIP: Each time to start a new seam run, charge/load the head of the automatic taper with compound by doing a quick 5 to 6” spin of your drive wheel against the wall without advancing the tape; this will ensure that when the tape advances it is fully coated with compound.

- On flat seams, always use the automatic taper at a slight angle to the wall or ceiling so that only one side of the drive wheel is touching. If you run the taper flat against the wall, too much of the joint compound will squeeze out from behind the tape.

- PRO TIP: During a long flat seam run on a ceiling, rock the taper from one side of the drive wheel to the other side every 2 - 3 feet; this action will ensure the mud and tape stays in place until you’ve had a chance to bed the tape down with a trailing knife.

- On inside corner seams, keep your taper as close to 45 degrees as possible, so that both wheels are touching the two walls or the ceiling and the wall. This will make sure tape is centered correctly in the seam as you push it in place with the creaser wheel.

- Inside corners generally have more drag than flat seams. When taping these angles, give yourself a few extra inches of lead tape at the start of the run. This extra tape will compensate for any movement in the tape as you move across the seam.

- When you get to the end of a seam or a corner, cut the tape 3” to 4” before you finish. Then let the remaining tape roll over the drive wheel and into the corner. With a little practice, you will be able to cut to the perfect length every time.

- PRO TIP: If you feel that you have cut the tape a little short, gently pull up on the tape with your hand from partway down the wall. You should be able to center the tape a bit and close the gap.

- Always stop the automatic taper completely before activating the control sleeve to cut the tape. Otherwise the tape won’t cut properly at a right angle to the taper and could double cut even jam up your tape.

- Before you use your automatic taper, always oil up all moving parts liberally with 3-in-1 machine oil. DO NOT use the original WD-40, as it is caustic and will break down your gaskets and plunger. In fact, we don’t recommend you use any lubrication that is in a spray can, unless you know what the propellant is. Often it is benzyne, which is also very hard on gaskets and seals. We highly recommend common machine oil such as 3-in-ONE

- Once you’ve finished cleaning your taper, we suggest liberally coating all moving parts and the inside of the tube with 3-in-ONE oil again. It will displace the water and reduce any opportunity for corrosion.

- PRO TIP: You can make short work of cleaning your taper by getting a small electric pressure washer.

- When cleaning your automatic taper do not force the plunger towards the head by jamming a rod, stick or anything else from the bottom and pushing against it. This could cause your cable to become caught up at the head and potentially snap it.

- PRO TIP: Automatic tapers have several small wearable parts. To minimize any downtime on the jobsite, we recommend you purchase an in-field repair kit (#5-815) that includes most of parts that are often replaced - blades, needles, cable, springs, etc.

PRODUCT INFO

FAST FREE SHIPPING

ACROSS THE CONTINENTAL USA

LEVEL5 will cover the standard shipping costs for all orders over $50 across the continental USA.

Orders delivered throughout the continental USA will be shipped via UPS or FEDEX Ground. Delivery times vary between 2 to 5 business days depending on where you are located in relation to our headquarters in Kansas City, KS.

The "Continental United States" refers to the 48 contiguous states and the District of Columbia, but excludes Alaska, Hawaii, Puerto Rico or the other U.S. territories and military posts.

Want faster shipping? Call us at 800.227.7713 . For orders received before 10am Central Time, we can ship overnight to most regions in the USA.

OTHER REGIONS

LEVEL5 Tools ships worldwide!

For Alaska, Hawaii, Puerto Rico, other U.S. territories and military posts, as well as international locations, call us at 800.227.7713 (USA and Canada) or 913.608.8530 for an accurate quote including shipping. English y español.

To quote your order, we will need the following details:

- First and Last Name

- EXACT Shipping Address

- Mobile Number

- Email Address

- A list of the tools you wish to purchase

Please note that your order will be transacted in US dollars and your credit card company or bank will perform the conversion to your native currency on your behalf.

METHOD OF SHIPMENT

All merchandise destined for outside the continental US will be shipped via air or ocean. Rates and delivery times for international parcel shipment will vary based on carrier, delivery method, and speed of shipment required. You are responsible for the freight charges and all invoices are prepaid before shipment.

DUTIES & CUSTOMS

Your country may charge additional fees in the form of duties, border clearing costs, taxes, etc. that would be in addition to the quote we are providing you. It is your responsibility to understand what these additional costs might be. Your country may hold your order at the border until you have paid them these additional fees. WE HIGHLY RECOMMEND you contact an international shipping broker in your country who can assist you with understanding any additional costs associated with importing your tools and can make the importation easy for you by handling the logistics and paperwork on your behalf.

THE LEVEL5 30-DAY, “NO-HASSLE” POLICY

We believe it is important that you have some time to evaluate the design, quality, fit and finish of your LEVEL5 tools before fully committing to their use. Therefore, if you aren't 100% satisfied, you have a period of 30 days from purchase to return any UNUSED tools you've purchased directly from LEVEL5 Tools LLC.

Once your tools have been received in good order at our facility, you will receive your choice of a credit or refund of the original price. Please note that refunds must be applied against the same credit card you used to make the original purchase.

You will be responsible for any return shipping expenses. We recommend you insure your shipment with your shipping agent (FEDEX, UPS, USPS, etc.), as you are responsible for any damage to the tools during the return shipment. To assist with offsetting these return shipping costs, LEVEL5 will provide you with a one-time use coupon code for our website equal to the return shipping amount (a copy of the shipping receipt is required).

TERMS & CONDITIONS

If you wish to return your LEVEL5 tools within the 30-day evaluation period:

- The tools must be returned in the original packaging, including any internal bags, foam inserts, internal boxes, and/or shipping boxes - to ensure the tools are protected during delivery back to our facility.

- The tools must be unused and undamaged, so they can be resold as new, in order to receive a full refund of the purchase price.

- UNUSED TOOLS - Any unused tools received that are damaged in any way so that they cannot be resold as new will need to be refurbished. This requires us to charge you a 25% restocking fee.

- USED TOOLS - Any used tools received will need to be cleaned of joint compound, refurbished and sold at a discount. We will charge you a 50% restocking fee OR return the used tools back to you if preferred. You will be responsible for paying any corresponding shipping charges if you wish to have the tools returned.

- Any tools that are received damaged and cannot be refurbished and resold will discarded and will not qualify for a refund. You will have the option to have the tool(s) returned to you, but you will be responsible for paying any corresponding shipping charges

If you have any questions regarding this return policy, please reach out to us toll-free at 866.562.4229 (local: 913.608.8530).

7-Year Warranty

100% Satisfaction Guaranteed

LEVEL5 makes workhorse drywall finishing tools that set the standard for quality & reliability.

We back all of our tools with the strongest warranties in the industry and work hard to provide our family of finishers with the best customer service possible.

Do you have questions about your LEVEL5 Tool(s)? Call our toll-free support line at 866.562.4229 (local: 913.631.0804) or send us an email at support@level5tools.com. Our support team is available Monday through Friday, 7:30am to 4pm Central Time.

Manufacturer's Warranty

For its full line of automatic drywall finishing tools and accessories, LEVEL5 Tools, LLC. ("LEVEL5") offers a full seven (7) year warranty to the original owner that these products will be free from defects in material and function. This warranty is valid only in the USA, Canada, Australia, the United Kingdom and Europe. A one (1) year warranty applies in all other countries/markets.

Terms & Conditions

- The Warranty applies to the original owner and is not transferable.

- The Warranty is limited to repair or replacement of the product, and does not cover direct, indirect, consequential, incidental or any other type of damage resulting from its use.

- The Warranty does not cover normal wear, misuse, negligence, fire, theft, loss or intentional damage.

- All shipments to the LEVEL5 facility must be freight paid. LEVEL5 reserves the right to determine whether to repair or replace any product covered under the Warranty. Discontinued products may be replaced with newer models when necessary.

Parts and Components

Taper Wheel Assembly, 2nd Gen [#7218]

Schematic #

#

Part #

Description

Price

Add to Cart

1

7047

4-40 x3/16 Bind Head Screw

$1.00

2

7077

Taper Wheel

$14.00

3

7090

Drive hub

$15.00

4

7078

Taper Wheel Spool

$28.66

5

7070

8-32 x 1/4 FH Screw

$1.00

Gooser Assembly, 2nd Gen [#7293]

Schematic #

#

Part #

Description

Price

Add to Cart

1

7042

6-32X3/16 Fillister Head Screw

$1.00

2

7041

Gooser Needle Holder

$9.59

3

7023

Gooser Body

Not Available

$0

4

7019

Needle Spring

$3.00

5

7025

Magnet Assembly

$10.12

6

7030

4-40 x 1/4 Bind Head Screw

$1.00

7

7031

#4 Lock Washer

$1.00

8

7010

6-32 x 5/16 Round Head Screw

$1.00

9

7022

Needle Holder Lock

$2.64

10

7040

Needle Gooser

$1.00

Cover Plate Assembly, 1st Gen

Schematic #

#

Part #

Description

Price

Add to Cart

1

7034

Disengaging Rod Bearing

$8.76

2

7033

O'Ring

$0.47

3

7032

O'Ring Housing

$14.47

4

7042

6-32X3/16 Fillister Head Screw

$1.00

5

7013

#6 Lockwasher Medium

$1.00

6

7045

Cover Plate

Not Available

$0

7

7126

4-40 x 5/16 BH Screw- Fastenal 70657

$1.00

8

7017

6-32 x 3/8 Bind Head Screw

$1.00

9

7029

Bracket Base

$5.23

10

7014

Collar Bushing

$3.25

11

7016

Disengaging Cam

$6.00

12

7015

#6-32 Thin Pattern Locknut

$1.00

13

7028

Disengaging Rod (shaft)

$9.64

14

7248

4-40 Lock Nut

$1.00

Cutter Chain Assembly, 2nd Gen [#9333]

Schematic #

#

Part #

Description

Price

Add to Cart

1

7116

1/16 x 1/2in Cotter Pin Fastenal 74268

$1.00

2

7332

Cutter Chain without Spring

$65.00

3

7136

4-40 x 6.3MM FLH Screw, Phillips

$3.00

4

7111

Pyramid Blade

$2.00

5

7112

Cutter Block Clamp

$11.00

6

9108

Cutter Chain Spring

$12.00

7

7054

Key Ring

$1.00

8

9917

AT Key Ring Holder

$16.00

9

7177

#10 Brass Washer

$1.00

10

9916

AT Wing Nut

$1.00

Taper Head Assembly, 2nd Gen two

Schematic #

#

Part #

Description

Price

Add to Cart

1

7083

Tape Guide Assembly

$50.00

2

7075

6-32 x 1/2 FillisterHeadScrew

$1.00

3

7013

#6 Lockwasher Medium

$1.00

4

7074

Tape Guide Support Bracket

Not Available

$0

5

7399

4-40 X 8mm FH Screw, Philips

$1.00

6

7081

Bushing Head

$7.20

7

7012

#6-32 x 1/4 Fillister Head

$1.00

8

9082

New Style Taper Head

$99.00

9

7071

Bushing, Head

$8.40

10

9665

Right Side Plate- Taper

$27.00

11

7047

4-40 x3/16 Bind Head Screw

$1.00

12

9913

Taper Brake Pin Screw

$1.00

13

7092

Cutter Block Tube

$10.00

14

7037

Chain Roller Support (Right)

$8.24

15

8288

#8-32, SS, Nylon lock, Hex nut

$1.00

16

9125

Cutter Chain Bushing (metal) Taper

$5.00

17

9122

Cutter Chain Roller (white) Taper

$1.50

18

7020

Chain Keeper

$1.00

19

7105

8-32 x 5/8 TH Screw

$1.00

20

7127

4-40 x 3/8 FH Screw Fastenal 0170759

$1.00

21

7248

4-40 Lock Nut

$1.00

22

7126

4-40 x 5/16 BH Screw- Fastenal 70657

$1.00

23

7444

Screw

Not Available

$0

24

7031

#4 Lock Washer

$1.00

25

7124

Bearing Bracket

$3.00

26

7087

SS UCFSL MS 4-40 x 1/8 FH Screw

$1.00

27

7096

Taper Filler Tube Assembly

$25.00

28

7050

3-48 Lock Nut

$1.00

29

7051

Valve Spring

$3.00

30

7053

Valve Assembly

$10.00

31

7038

2/56 x 1/8 Bind Head Screw

$1.00

32

7039

Baffle Plate Assembly

$12.88

33

9061

AT Taper Runner

$22.00

34

7063

Bearing Nyliner

$1.50

35

7005

Lock Roller Assembly (Brake)

$10.00

36

7035

Anvil

$12.00

37

9007

Roller Axle Spring (Brake Pin)

$5.00

38

9912

AT Brake Pin Holder

$49.00

39

9914

AT Washer

$2.00

40

9915

AT Brake Adjuster

$3.00

41

9911

AT Washer

$1.00

42

9910

AT Ball Screw 6-32x6.3

$1.00

43

7448

Block

Not Available

$0

44

9008

Drip Guard

$7.00

45

9085

AT Tape Guide Runner

$22.00

46

7445

Screw

Not Available

$0

47

9043

Gooser Release Cam

Not Available

$0

48

7447

Main Cutter Chain Roller (white) Taper

$1.50

49

9129

Main Chain Guard

$5.00

50

9114

Chain Roller Support (Left)

$9.00

51

7088

6-32 X 1/4 FH Screw

$1.00

52

9086

Left Side Plate- Taper

$22.00

53

7113

Tie Rod

$22.00

54

7072

3-48 Miniature Hex Nut

$1.00

55

7446

Screw

Not Available

$0

56

7119

Nyliner Bearing-Straight

$2.75

57

7322

Bearing

$2.00

Taper Tube Assembly, 2nd Gen one

Schematic #

#

Part #

Description

Price

Add to Cart

1

7170

6-32 x 3/16 Round Head

$1.00

2

7169

Tube Protector

$17.00

3

9998

AT Tape Roll Holder

$38.00

4

7235

Taper Band Screw

$1.50

5

8288

#8-32, SS, Nylon lock, Hex nut

$1.00

6

7164

Tape Spool

$12.00

7

7287

Control Tube Assembly

$113.00

8

9999

AT Extension Arm Guide

$4.00

9

7144

Control Extension Arm

$34.99

10

7315

Washer Retaining

$1.00

11

7055

Gooser & Cutter Chain

$3.75

12

7117

Cutter Chain Tube

$10.00

13

7116

1/16 x 1/2in Cotter Pin Fastenal 74268

$1.00

14

7344

Taper Head Assembly

$600.00

15

7013

#6 Lockwasher Medium

$1.00

16

7012

#6-32 x 1/4 Fillister Head

$1.00

17

7198

Creaser Connector Assembly

$28.00

18

7137

Cable

$7.99

19

7135

1/4-20 Hex Nut

$3.00

20

7131

1/4-20 Hex Castle Nut

$7.25

21

7133

Plunger Cup Washer

$7.25

22

7132

Plunger Cup

$28.99

23

7130

Plunger

$32.00

24

7134

1/4-20 X 3/4in HH Screw

$4.00

25

7168

S-Hook

$2.00

26

7166

Taper Tube

$259.99

27

7178

#14 Brass Washer

$1.00

28

7165

Creaser Trigger

$42.00

Drive Dog Assembly, 2nd Gen [#7097]

Schematic #

#

Part #

Description

Price

Add to Cart

1

7094

Spring Drive Dog

$2.00

2

7269

Drive Dog Body

Not Available

$0

3

7060

Drive Dog Screw 8-32

$1.00

4

7116

1/16 x 1/2in Cotter Pin Fastenal 74268

$1.00

5

7100

Cable Drum Shaft

$27.00

6

7089

Drive dog roller

Not Available

$0

Taper Wheel Assembly, 2nd Gen [#7218]

Gooser Assembly, 2nd Gen [#7293]

Not Available

Cover Plate Assembly, 1st Gen

Not Available

Cutter Chain Assembly, 2nd Gen [#9333]

Taper Head Assembly, 2nd Gen two

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Taper Tube Assembly, 2nd Gen one

Drive Dog Assembly, 2nd Gen [#7097]

Not Available

Not Available

Wear Parts

When you purchase professional drywall finishing tools, it is important to know that common wear parts are readily available to ensure your tools are run optimally for their entire operating life.

At LEVEL5, we maintain a large inventory of wear parts for all models of our drywall taping and finishing tools, including:

- Automatic taper cutting blades

- Flat box and corner finisher blades, shoes, etc.

- Gaskets & o-rings

- Plungers

- Springs

- Wheels & bearings

- Screws

- and much more...

These components are available separately or in convenient logical kits for tool maintenance or rebuilds. Perhaps most importantly, these components and kits are available at a reasonable price!

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10559/4-760_2__53588.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10560/4-760_3__26730.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10561/4-760_4__61440.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10562/4-760_5__17597.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10563/4-760_6__35781.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10564/4-760_7__46118.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10565/4-760_8__57968.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10566/4-760_9__19037.1743190838.jpg?c=1)

![Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen] Automatic Drywall Taper w/ Quick-Clean Head [2nd Gen]](https://cdn11.bigcommerce.com/s-89a9ntp16/images/stencil/50x50/products/501/10567/4-760_10__06836.1743190838.jpg?c=1)